Supplier Performance Management (SPM) Lifecycle and Process:

Our effective method for optimizing supply chains involves a six-phase Supplier Performance Management (SPM) lifecycle, along with the necessary processes and tasks to ensure compliance with flow-down requirements. This approach enables us to assist both customers and suppliers in delivering quality products on time.

1. Supplier Selection

• Task: Evaluate and select suppliers based on capability, quality systems, and

past performance.

• Tools: Supplier audits, RFQs, and vendor evaluation scorecards.

• Goal: Ensure suppliers meet initial qualifications and align with customer

requirements.

2. Supplier Onboarding

• Task: Formalize agreements, share flow-down requirements, and establish

communication protocols.

• Tools: Contracts, supplier manuals, and compliance checklists.

• Goal: Align supplier processes with compliance and quality standards.

3. Performance Monitoring

• Task: Continuously track supplier performance metrics, including delivery

times, quality, and cost.

• Tools: KPIs, dashboards, and periodic scorecards.

• Goal: Ensure ongoing alignment with performance and compliance expectations.

4. Feedback and Improvement

• Task: Provide suppliers with regular feedback and request corrective actions

for performance gaps.

• Tools: Performance reviews, root cause analysis, and corrective action plans

(CAPAs).

• Goal: Foster continuous improvement and stronger supplier relationships.

5. Risk Management and Mitigation

• Task: Identify risks, monitor potential disruptions, and develop contingency

plans.

• Tools: Risk assessments, dual sourcing, and supply chain mapping.

• Goal: Minimize the impact of supplier-related risks on overall operations.

6. Supplier Phase-Out (if necessary)

• Task: Gradually disengage with underperforming suppliers while ensuring

smooth transitions.

• Tools: Transition plans and detailed handoffs.

• Goal: Protect supply chain continuity and maintain compliance.

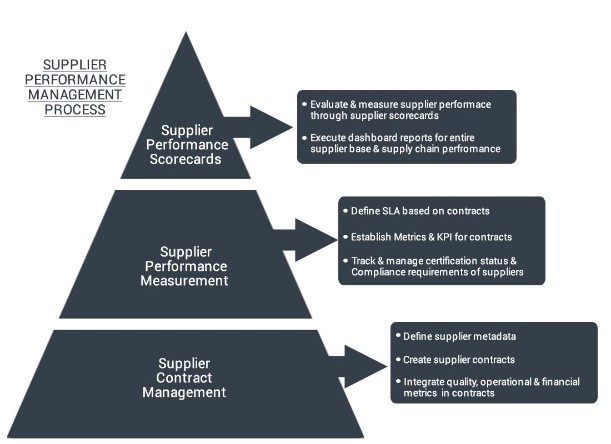

SPM Process

1. Define Requirements

• Communicate customer flow-down requirements (e.g., regulatory, quality, and

technical standards).

• Document expectations in agreements and supplier manuals.

2. Set Performance Metrics

• Establish measurable KPIs: on-time delivery (OTD), defect rates, and cost

variances.

• Align metrics with customer needs and contractual obligations.

3. Conduct Supplier Audits

• Perform regular audits to verify adherence to requirements.

• Address non-conformances through corrective actions.

4. Monitor and Analyze Data

• Use real-time tracking systems to measure supplier performance.

• Analyze trends to identify improvement opportunities.

5. Drive Continuous Improvement

• Engage suppliers in collaborative problem-solving.

• Share best practices and provide training resources.

6. Ensure Compliance with Flow-Down Requirements

• Track adherence to customer-specific flow-downs (e.g., technical specs, legal

requirements).

• Verify traceability and documentation accuracy throughout the supply chain.

Tasks to Ensure Compliance with Flow-Down Requirements

• Communicate Clearly: Provide suppliers with detailed flow-down requirements.

• Implement Robust Contracts: Ensure agreements include clauses for compliance

and audits.

• Trace Documentation: Maintain a record of compliance evidence at each stage

of production.

• Audit Regularly: Conduct compliance-focused audits to verify adherence to

flow-downs.

• Train Suppliers: Offer training programs to ensure understanding of flow-down

obligations.

• Monitor Supplier Sub-Tiers: Extend compliance checks to sub-tier suppliers to

prevent weak links.

By effectively managing the SPM lifecycle and ensuring compliance with

flow-down requirements, organizations create a reliable supply chain that

consistently delivers quality products on time while meeting customer and

regulatory expectations.